INTRODUCING: The RotoMAAK

Rotational Casting, also known as Rotocasting or Hollow Casting, is a molding process for creating many kinds of items, mostly hollow in form and typically made of plastic. The RotoMAAK rotocaster was born out of the desire to have a process by which Makers could scale up production of parts using rotational casting technology when 3D printing a small production run becomes cost and time prohibitive.

HOW DOES IT WORK?

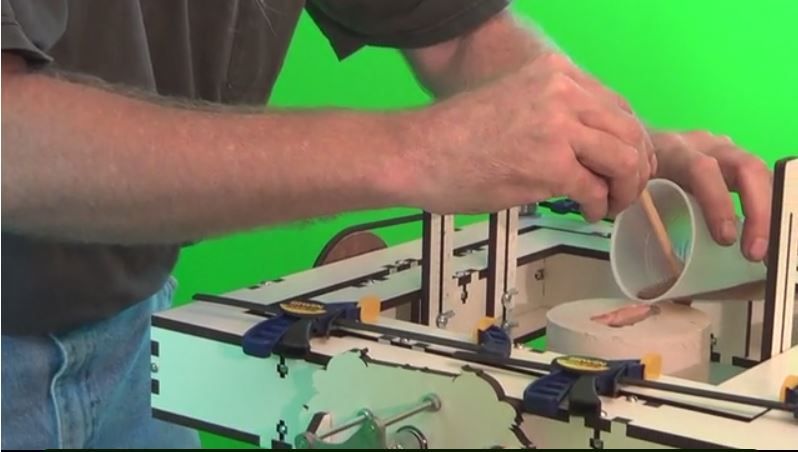

The RotoMAAK rotational caster consists of a hollow mold and a rotational device that spins the mold in a uniform motion. The hollow mold is filled with a charge or shot weight of air cure resin. It is then inserted into the RotoMAAK where it is slowly rotated (usually around two perpendicular axes) causing the liquid resin to uniformly disperse and stick to the walls of the mold where it slowly cures over time into the shape of the part. In order to maintain an even thickness throughout the part, the mold continues to rotate at all times during casting phase and curing phase. The continuous rotation of the mold also avoids sagging and part deformation.

The rotocasting process was applied to plastics in the 1940’s, but in its early years was rarely used due to a slow process and restriction to a small number of plastics. Over the past two decades, improvements in process control and developments with air cure resin and plastic powders have resulted in a significant increase in its usage for part production.

View the KickStarter at: www.kickstarter.com

Or Visit the Website at: www.rotomaak.com

Contact: Mark VanDiepenbos

Email: Mark@rotomaak.com